what are the key conditions for the quality of tpu film?

- 2023-06-09

- Fulian TPU film Professional Manufacturer in China

- 1151

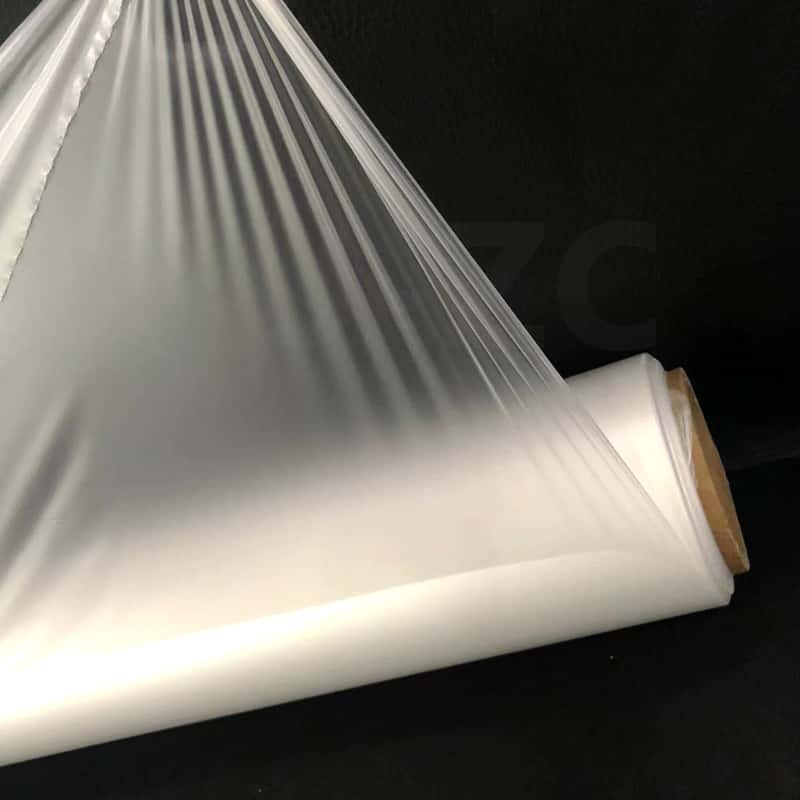

tpu filmit is a high-performance plastic film that is widely used in various fields due to its excellent properties. how to ensureTPUthe excellent quality of the film, thereby ensuring its effectiveness and reliability, has become an issue that manufacturers, engineers and users need to pay attention to. undertpu film manufacturersthe key conditions for the quality benefits of tpu films will be discussed from the aspects of physical and chemical properties, processing technology and quality control.

1. physical and chemical properties

1.1 ingredients and proportions

the thin composition of tpu is an important factor affecting its physical properties. reasonable tpu composition and ratio can determine its hardness, tensile strength, elastic modulus and wear resistance, thereby ensuring the mechanical strength and service life of the film. generally speaking, tpu films with a hardness of up to 80a have strong wear resistance but low elastic modulus; while tpu films with a hardness of 60a have a high elastic modulus and good wear resistance.

1.2 melt fluidity

the rheological properties of the melt are a key factor affecting the processing of tpu films. factors that affect the fluidity of tpu melt include melting point, molecular weight, step decomposition temperature and additives. reasonable adjustment of these parameters can achieve good processing fluidity and thick plate uniformity, thereby ensuring the flatness and thickness stability of the film.

2. processing technology

2.1 melt temperature

the processing temperature of tpu film is a very critical parameter. processing temperatures that are too high can easily lead to poor melt flow and loose films, while processing temperatures that are too low can easily lead to film breakage and poor surface quality. during the production process, the melt temperature should be controlled according to specific conditions and a reasonable production process should be established.

2.2 mold design

mold design is another key factor in determining film structure and surface quality. the design of the mold should consider the thermal expansion and contraction coefficient and thermal conductivity coefficient of the material, and reasonably arrange the thickness and reinforcement parts of the film to ensure uniform thickness and strength matching of the film. in addition, attention should be paid to the selection of materials with high thermal conductivity and the design of the heat dissipation system to ensure that the mold can maintain good processing performance even under long-term operation.

2.3 environmental conditions

environmental conditions have an impact on tpu film processing. during the production process, attention should be paid to controlling the temperature and humidity of the processing environment to avoid thermal deformation and surface defects. at the same time, attention should be paid to purifying dust in the fan system to ensure the cleanliness of the production workshop and avoid contaminating the film during the production process.

3. quality control

3.1 detection method

the quality control of tpu films requires a variety of detection methods. among them, hand feel, tensile strength, abrasion resistance and melt fluidity are the main indicators to judge the quality of tpu film. it is necessary to master the operating skills of these detection methods, and timely adjust the production process parameters based on the detection results to maintain the stability and reliability of film quality.

3.2 quality requirements of raw materials

the quality standards of tpu films have certain requirements. first, the quality of raw materials is required to meet international standards, which can be measured in terms of performance and stability. production standards must be strictly followed when selecting raw materials, and necessary testing and identification of each batch of raw materials must be carried out to ensure that the materials applied for film meet quality standards.

3.3 special process requirements

special process requirements help improve the quality of tpu films. for example, vacuum drying and low differential pressure spraying can avoid problems such as moisture absorption and impurity contamination of raw materials, thereby improving the stability and quality of the film.

in summary, only by determining the key conditions such as the physical and chemical properties, processing technology and quality control of the tpu film can we ensure the excellent performance of the tpu film and improve its application prospects in various fields.

Related Information

-

透明tpu薄膜的环保性能如何

-

tpu膜在医疗用品中的应用有哪些

-

高弹TPU薄膜拉伸性能如何测试

-

What is the environmental performance of TPU film for luggage?

-

What are the characteristics of TPU waterproof and breathable membrane for outdoor products?

-

What are the applications of TPU hot melt adhesive film in automotive interiors?