how to use tpu hot melt adhesive film

- 2023-01-14

- Fulian TPU film Professional Manufacturer in China

- 571

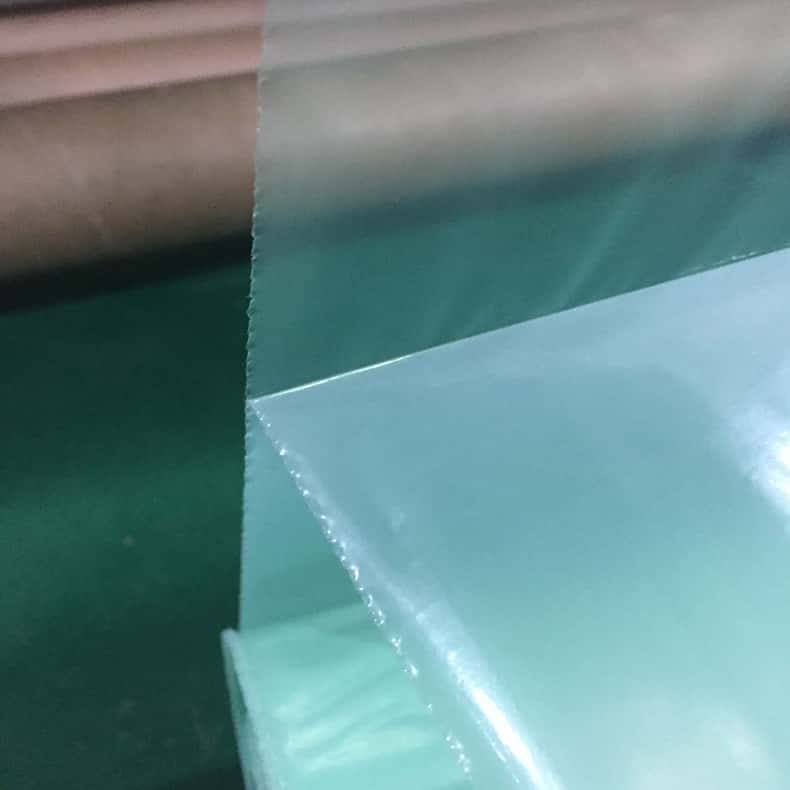

tpu hot melt adhesive film is an adhesive product that is efficient, environmentally friendly and clean. when many people first came into contact with tpu hot melt adhesive film products, they didn't know how to use something like a plastic film and thought it was magical. in fact, the use of tpu hot melt adhesive film is very simple, but it needs to be distinguished according to different applications and process equipment.

to put it simply, when using tpu hot melt adhesive film, it is necessary to heat it at high temperature to melt the adhesive film. only the melted glue in the liquid state can infiltrate the surface of the adherend. at the same time, a certain amount of pressure is applied, and the hot melt adhesive film waits for the film to melt again. after cooling and hardening, the glue itself forms a cohesive force, which creates bonding strength and bonds the adherends together. the use of hot melt adhesive films is mainly divided into large-area lamination and small-area bonding.

if it is a large-area lamination, a lamination machine is generally used for lamination, which is generally used in the lamination processing of textiles, clothing fabrics, leather products, foam products and other rolled materials. generally, laminating factories use large roller laminating machines. as long as the previous glue tank is replaced with a bearing that can carry hot melt adhesive film tape materials, it can be used normally. when using, adjust the temperature of the composite drum to the hot melt adhesive film process temperature, sandwich a layer of hot melt adhesive film between the materials to be compounded, and enter the compound drum together. the three layers of materials will follow the drum and come out in a circle to be compounded together. .

for the above categories of materials, if the format is small, an ironing and interlining machine is often used to laminate them.

in addition, we have also encountered the lamination of products that are not coiled materials, such as the lamination of plates or metal plates. we often use a hot press to laminate. spread the hot melt adhesive film between the two layers of boards that need to be bonded, and then put them into the hot press together to press them together. after hot pressing for a period of time, take them out and wait for them to cool down. it is worth mentioning that when bonding plates like this, the material will often produce thermal stress after hot pressing, so there is often stress shrinkage during the cooling process, causing the plate to deform to a certain extent, and the heat the melt adhesive film must wait until it is completely cooled and hardened before the bonding strength can reach its best, so degumming will often occur due to deformation during the cooling process. therefore, generally when using hot melt adhesive film to bond such boards, a cold pressing process is required. only after the hot melt adhesive film is completely cooled can the pressure be removed to achieve the best bonding strength.

in addition to the above large-area bonding, there are also many cases of small-area bonding. for example, the hot melt adhesive film used in the production process of non-marking clothing is often completed by a seamless splicing machine. this kind of machine using high-frequency hot melt technology as the principle, it can quickly heat the splicing parts and achieve rapid bonding between fabrics. in addition, some small area bonding can also be done manually using relatively primitive methods such as electric irons, flat irons, heat sealers, heat guns and other equipment.

what we need to pay attention to is that in the use of hot melt adhesive film, there are also requirements for heating and pressurizing time and pressurizing pressure. these parameters must be adjusted according to the material classification of the hot melt adhesive film. different materials have different physical and chemical indicators. , the process parameters during use are also different. hot melt adhesive film manufacturers often have a physical parameter label when the product leaves the factory. the operator should try to operate according to the recommended process on the physical parameter label. however, in the end, specific adjustments need to be made based on the actual process and equipment to achieve the process.

Related Information

-

What are the applications of TPU hot melt adhesive film in the clothing industry?

-

a brief analysis of the differences between tpu hot melt adhesive film and eva hot melt adhesive film

-

introduction to low temperature tpu hot melt adhesive film

-

how to use tpu hot melt adhesive film

-

what material is tpu hot melt adhesive film? what are the advantages?

-

application of tpu hot melt adhesive film in shoe material industry