tpu film chemistry principle

- 2023-04-06

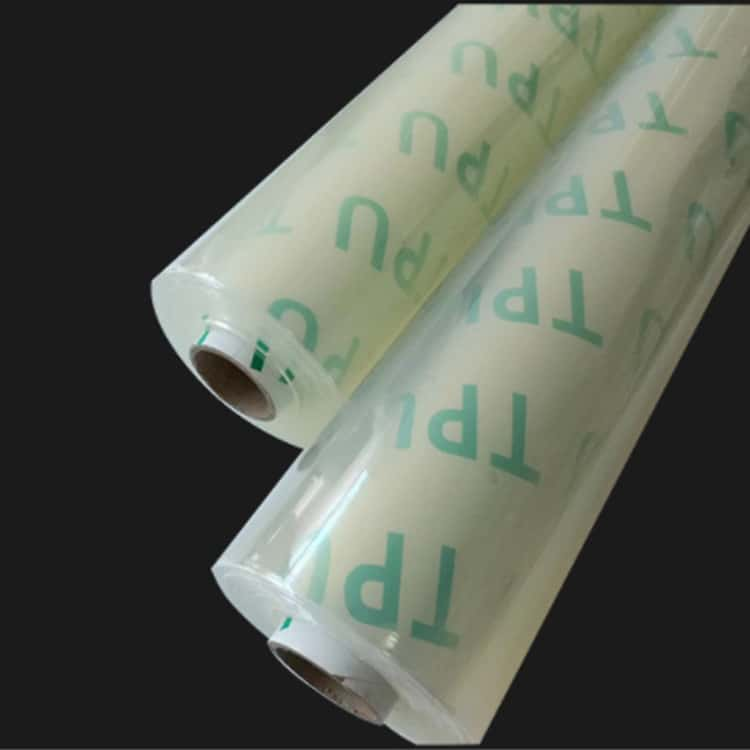

- Fulian TPU film Professional Manufacturer in China

- 489

introduction to the chemical principles of tpu films, the basic concept of tpu: thermoplastic polyurethane elastomer (thermoplastic polyurethane): it can be heated and plasticized. there is no or little cross-linking in the chemical structure. its molecules are basically linear, but there are certain physical cross-links. this type of polyurethane is called tpu.

tpu film has a wide range of properties, including high tensile strength and elongation, as well as excellent tear resistance and shear resistance, so it is very popular among people. its wear resistance is better than nylon, rubber, polystyrene or high-density polyethylene, so it is used in many applications. tpu film has good chemical resistance, uv resistance and hydrolysis resistance, excellent low temperature flexibility and excellent bending fatigue resistance. in addition, its transparency, dyeability and easy decoration make tpu an ideal material for various decorative purposes. the recyclability of tpu film makes it no environmental pollution problem.

tpu film has the elasticity of rubber and the rigidity of plastic, so it has been widely used. its versatility and durability make it stronger and tougher than traditional thermoset systems, and it can be processed in a variety of processes using plastics.

tpu film is a member of thermoplastic elastomers (tpe), and tpe is a polymer that can be molded and overmolded under heat and pressure. all tpus are formed from three main raw materials: diisocyanate, macrodiol and chain extender. the choice of each of these ingredients affects the structure of the polymer and therefore its final physical properties. some other raw materials are also used in the manufacture of tpu, such as stabilizers, lubricants, fillers and pigments.

tpu films have several properties that make them particularly suitable for use in the textile industry. its flexibility (especially low temperature flexibility) makes tpu products soft to the touch and silent. this material maintains good barrier properties while providing high breathing capacity, which is required by the outdoor work and sportswear industries. preventing the growth of mold, washability, rubber elasticity, tear and puncture resistance, and the ability to be processed into fibers have enabled tpu to successfully enter the textile manufacturing industry. there are also some tpus that provide antistatic properties, which are required for clothing worn in clean room environments.