how to solve the problem of air leakage in tpu film after high-frequency hot pressing?

- 2023-06-12

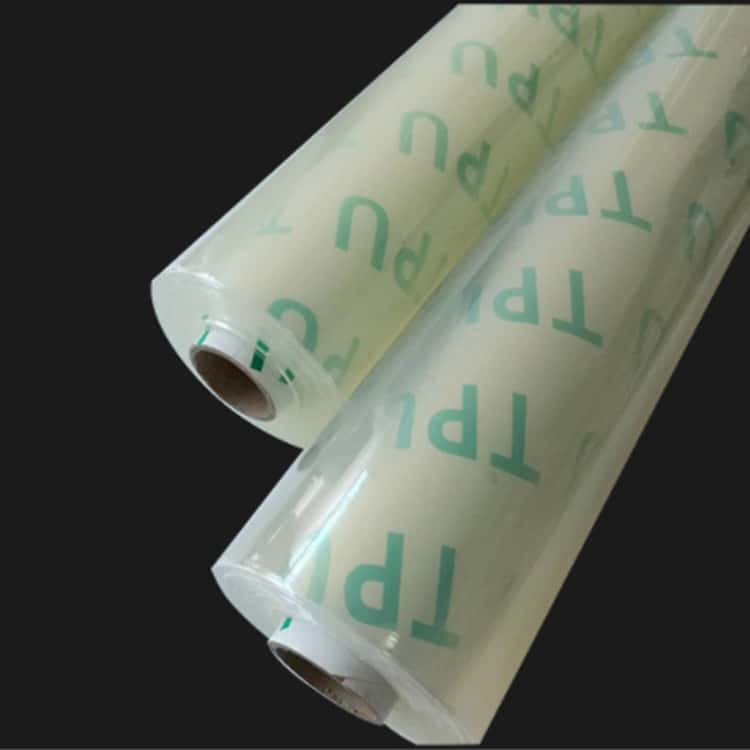

- Fulian TPU film Professional Manufacturer in China

- 892

tpu filmit is a thermoplastic plastic film that is very suitable for high-frequency and high-frequency hot pressing. however, even if this is the case, some people will still report that the products after hot pressing have air leakage and water leakage. what is the reason? how to solve it? lettpu film manufacturersanalyze it for you!

1.TPUthe film material itself is a problem.

the air tightness of tpu film is very good, especiallypolyester tpu film, generally will not leak. however, it cannot be ruled out that holes may occasionally appear in the relatively thin tpu film, which may lead to air leakage. our experience is that if the thickness exceeds 0.1mmtpu filmthere will be no air leakage from the material itself. air leaks below 0.1mm are also rare, and liquid leaks are possible (choose the right material for this). it is recommended to choose blown film products below 0.1mm because the film is blown with pe and other base materials. if there is air leakage, the film itself will not form.

2. high-frequency mold problems.

in the case of air leaks, high frequency molding is often the first step in troubleshooting. high-frequency mold damage, deformation, unevenness, unreasonable design, too deep or too shallow, mismatch between the upper and lower molds, mismatch with the nozzle position, etc. may lead to air leakage. in this case, it is necessary to ask a skilled master to take more materials for pressure testing, or even modify the mold to solve the problem.

3. processing technology.

they mostly occur at the connection between the tpu film and the air nozzle, but rarely at the contact between the film and the air nozzle. if it occurs in the part where the film is in contact with the film, one possibility is that the processing temperature is too low, and the film and film are not fused together under real high frequency, resulting in "virtual welding" and natural gas leakage. another reason is that the processing temperature is too high, the film and film are pressed too tightly, and the thickness of the edge part is too thin. even if it is cut, air leakage will occur.

if it occurs at the connection between the tpu film and the air nozzle, there may be several situations. one is that the materials of the tpu film and the nozzle do not match. the air nozzle is made of pvc or polyether and cannot be fused with polyester's tpu film. one situation is that the hardness of the tpu and the nozzle do not match. the nozzle hardness is too high. the tpu film is squeezed and the nozzle is not melted. another situation is that the mold does not match and is uneven, causing part of the mold to be pressed firmly and part not to be pressed firmly, causing natural air leakage.

the above is the answer to this question. if you have other questions and needs, please feel free to contact us!

Related Information

-

tpu waterproof breathable film environmentally friendly ultra-transparent 0.6mm

-

a brief analysis of the differences between tpu hot melt adhesive film and eva hot melt adhesive film

-

tpu film manufacturers tell you the advantages of tpu film

-

tpu film manufacturers explain the applicable industries of the film

-

briefly introduce the three processes of tpu film production and their differences

-

a brief analysis of the properties of tpu films